Crescent Alfa Series Cyclone Type Powder Spray cum Recovery Booths

The contoured design of the Alfa Series Cyclone Type Booths ensures uniform air flow throughout the booth cross-section. Absence of dead pockets ensures easy cleaning and the charged powder surrounds the article uniformly resulting in higher transfer efficiency.

The contoured design of the Alfa Series Cyclone Type Booths ensures uniform air flow throughout the booth cross-section. Absence of dead pockets ensures easy cleaning and the charged powder surrounds the article uniformly resulting in higher transfer efficiency.

Crescent Booths are known for:

- Optimum Powder Recovery

- Easy Cleaning

- Faster Colour Change

- Can be fitted with material handling system suitable to the customer requirement such as loose track, trolley or the overhead conveyor.

- Powder recovery system: single or Multi cyclone type.

STANDARD BATCH – PRODUCTION MODELS

| CAS 900 |

1150 X 900 X 1350 |

900 X 900 |

2.0 HP |

| CAS 1200 |

1500 X 1200 X 1500 |

1200 X 1200 |

3.0 HP |

Crescent Delta Series Latest Generation Filter Cartridge Powder Spray cum Recovery Booths

Crescent Delta series Filter Cartridges Powder Spray cum Recovery Booths are latest in series with International Technologies offering :

Crescent Delta series Filter Cartridges Powder Spray cum Recovery Booths are latest in series with International Technologies offering :

- Higher recovery efficiency of 98%.

- Makes colour changes easy and quick due to absence to any duct etc. to be cleaned.

- No contamination during colour changes.

- Reduces powder inventory needs, since fresh powder need not be mixed with recovered powder at the time of reuse.

- Maintains horizontal air flow pattern for more uniform coating results.

- The compact design of the machine occupies lesser shop-floor area.

- Can be designed for manual/conveyorised applications.

STANDARD BATCH – PRODUCTION MODELS

| CDS 100 |

900 X 900 X 800 |

1180 X 2100 X 1350 |

2.0 HP |

02 NOS. |

| CAS 120 |

1200 X 1000 X 900 |

1480 X 2100 X 1450 |

3.0 HP |

03 NOS. |

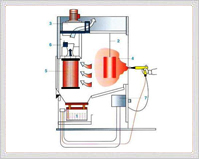

Operation :

The fresh powder is being fed in the hopper directly. The work-pieces are hung in the booth and sprayed with the powder. Specially designed low pressure high capacity blower sucks air and the over sprayed powder through the cartridge filters in a horizontal flat pattern. The powder particles are not permitted to pass through the filter cartridges, and it allows only the clean air to the atmosphere. The powder laden filter cartridges are regularly and automatically cleaned by electronically controlled high pressure reverse pulse jets of the compressed air. The powder thrown off the filter cartridge is collected in the powder hopper and is reused as such without mixing any fresh powder.

The fresh powder is being fed in the hopper directly. The work-pieces are hung in the booth and sprayed with the powder. Specially designed low pressure high capacity blower sucks air and the over sprayed powder through the cartridge filters in a horizontal flat pattern. The powder particles are not permitted to pass through the filter cartridges, and it allows only the clean air to the atmosphere. The powder laden filter cartridges are regularly and automatically cleaned by electronically controlled high pressure reverse pulse jets of the compressed air. The powder thrown off the filter cartridge is collected in the powder hopper and is reused as such without mixing any fresh powder.